Rotary Automatic Carbonated Drink Beer Canning Filling Machine

Production Line

Descriptions and Specifications of Equipment:

1 Carbonation Mixer

QHS series beverage mixer has the reasonable structure, high

precision mix, plenty CO2 mix. Mainly applies to all carbonated

beverages mixed processing, and can also be used for other

beverages. It is the main equipment in complete equipments of

carbonated beverage manufacturing.

Main features

1) Advanced mass flow in-line blending and carbonation for reduced

product & ingredient losses;

2) High efficiency deaeration

3) Simplified, user-friendly, operator interface

4) Automated “ no-dump” start-up capability

5) Complete product recipe management

6) Ingredient usage trending and totalling

7) Improved product yields and consistency

8) Reduced B.O.D. cost

9) Fast, favorable return-on-investment

Water De-aeration Water Carbonation Proportioning of water and

syrup Cooling System

2 Depalletizer

This equipment has a scientific process flow, reliable performance,

high degree of automation, simple operation and high cost

performance. It is an ideal packaging equipment for various

companies and is welcomed by the food and beverage industry and the

chemical industry.

MAIN STRUCTURAL FEATURES AND COMPOSITION

a. Mechanical structure is simple, solid, less land occupation, low

maintenance, long service life;

b. The whole machine is controlled by imported PLC, with multiple

safety protection, reliable operation and full automatic

operation;

c. Suitable for various stacking and bottle types, convenient

adjustment and high production efficiency;

d. With touch-screen control, friendly interface and easy

operation;

e. Using high quality conveyor chain segmented transmission, the

access section can be lengthened arbitrarily

f. Motor, cylinder drive and control are all imported famous brand

components

g. Try to use 304 materials, which meet the hygienic standard, the

machine is beautiful and generous.

TECHNICAL PARAMETERS

Model | XD200 |

Production capacity | 12000 cans/hour |

Applicable bottle | cans |

Compressed air consumption | 0.01M3 /min , 6~8bar |

Operating voltage(AC) | 380V |

Control voltage(DC) | 24V |

Total power | 6.37KW |

Total weight | 5000kg |

3 Can Rinser

It is used to clean empty can in canning production line. Empty

cans will be sent to turning device first, which will be turned

around then transferred into rinsing machine. Empty can will be

running from top to bottom along the turning device. When empty

cans enter into rinser, they will be cleaned by 80ºC hot water

(provided by customer) to reach aseptic state of can. There is

certain inclination angle in both sides of rinser, whose size could

be adjusted properly when needed. Empty cans will be rolling

in parallel way from top to end; the waste water will be discharged

from outfall.

Technical parameters

Required capacity | 0-200 CPM (330ml) |

Diameter of Can | 53~66mm |

Height of Can | 70~175mm |

Dimensions | 6200×470×310mm (L×W×H) |

Machine weight | 500Kg |

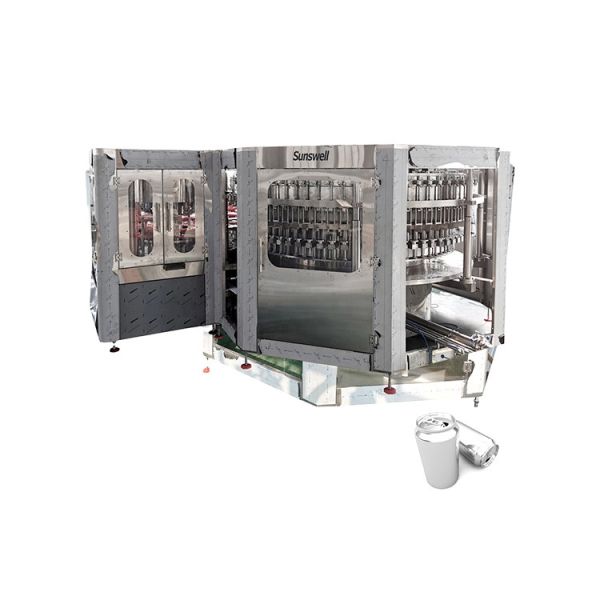

4 Can Filler/Seamer Monoblock

It is suitable for filling and seaming carbonated liquid such as

cola, beer, functional beverage, etc. It is equipped the advanced

device, electrical equipment, and pneumatic control technology. It

has the characteristics of filling reposefully, high speed,

liquid level control, seaming reliably, frequency conversion

timing, less material loss. It is the preferred equipment for

beverage plants.

Features

Wholly sealed widow structure which is beautiful, concise, easy

and highly operated;

Product tank design with precision polishing inside;

High precision and large flow rate filling valves to meet

productive requirement;

Specially designed roller structure which is easy to be adjusted,

locked and ensure sealing function;

Friendly and convenient operating panel with high expansibility.

Working Procedure

Cans will be pushed into can holding platform one by one by feeding

screw and star-wheel. Centering cup of filling valve will fall

to can; the distance between filling valves and cans is sealed by

springiness plastic ring. The movement of centering cup is

generated by plastic idler wheel along curvilinear motion. After

filled, valve will be closed and centering cup will rise from the

can. Filled can will be sent to conveyor chain, then to seamer.

Seamer will take lid, turn over the edge of can and turn the edge

to finish the sealing action by the control of cam. After that can

will be transferred to conveying system.